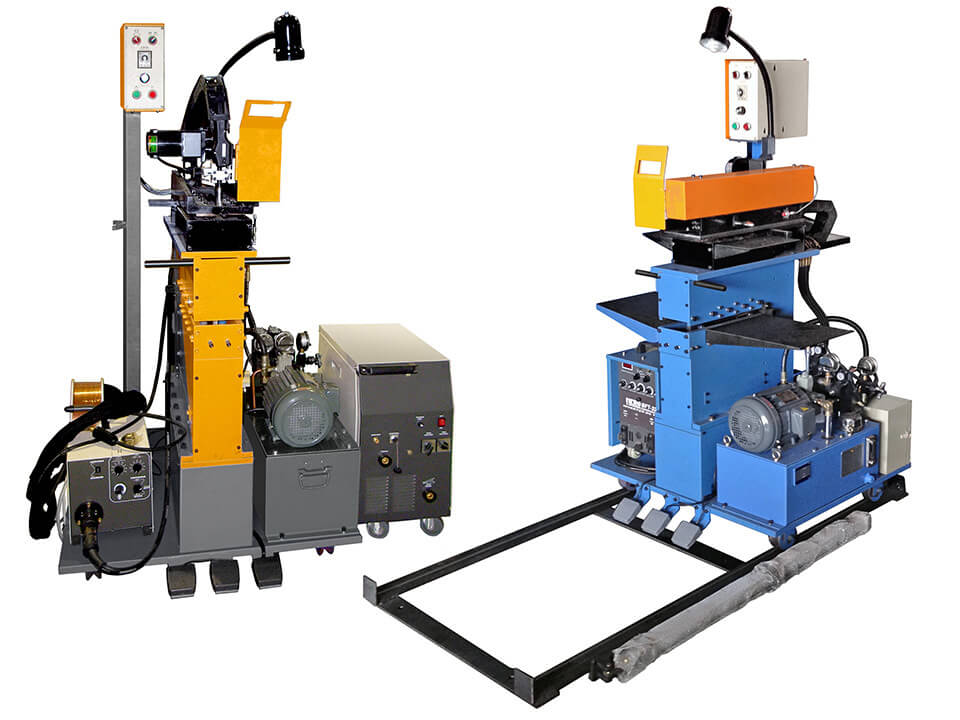

Coil Joint Welding Machine

Hydraulic dual pressure simple copper mold clamping, Air pressure simple copper mold clamping Utilize Rapid Cutting to Joint & Welding Coil. Construction patented. Hydraulic dual blades cutting, flat and straight for easy welding. Manual pneumatic or hydraulic simple copper mold clamping, automatic centering, accurate and fast operation.

Metal Cutting Welder

Construction patented. Hydraulic dual blades cutting, flat and straight for easy welding. Manual pneumatic or hydraulic simple copper mold clamping, automatic centering, accurate and fast operation. Adopt Precise Motor Control, Welding Gun Movement is Stable and Precise. Inverter TIG Welder to Ensure Welding Quality. Compact Construction and Suitable for Many Production Lines.

This product is the device used in metal cutting cutting cutting steel strip coils connected butt welding Stainless steel coil, steel, titanium steel plate steel plate, stainless steel, aluminum, copper Slitting Machine leveling machine cold rolling silicon steel production line of electronic parts stamping stamping industry pipe industry Forming Industry Round / Square Tube Makers (Such as Furniture Tubes, Decoration Tubes, etc.) Roll-Forming Rack Makers (Such as Window Slide Rack, Ceiling Rack, etc.) Continuous Press Makers (Such as Silic Chip and Electronic Parts Pressing, etc.)

Cold Rolling Mill Leveler Slitter Can be used with argon welding / minute current argon welding (TIG / MICRO), carbon dioxide welding machines CO2.

Electric plasma welding machine (PLASMA Welding) Laser Welding Machine (LASER). this machine has a high-frequency interference prevention function. Synchronous start welding functions, and is reversed switch.

Specifications

| Model | MC-250 ~ MC-1350 |

|---|---|

| Cutting Width | 250mm ~ 1350mm |

| Welding Width | 250mm ~ 1350mm |

| Workpiece Thickness | 0.2mm ~ 12mm |

| Cutting mechanism | Pneumatic - Hydraulic |

| Clamping mechanism | Pneumatic - Hydraulic |

| Input Power | AC3Ø 220V 380V 415V, 50/60Hz |

| Input Air supply | 6kg/cm² |

| Control System | Standard / PLC / HMI Control |

Acceptable special customized equipment.

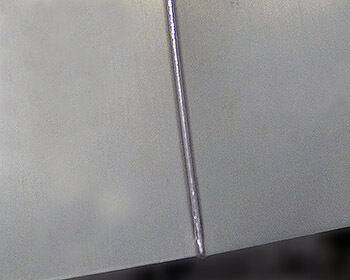

TIG Welding

Suitable for thin plate welding method, smooth metal surface weld bead.

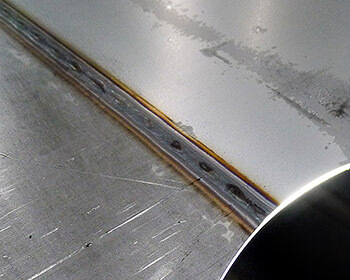

CO2/MAG/MIG Welding

Thick plate Welding method, Weld bead protrusion on metal surface.

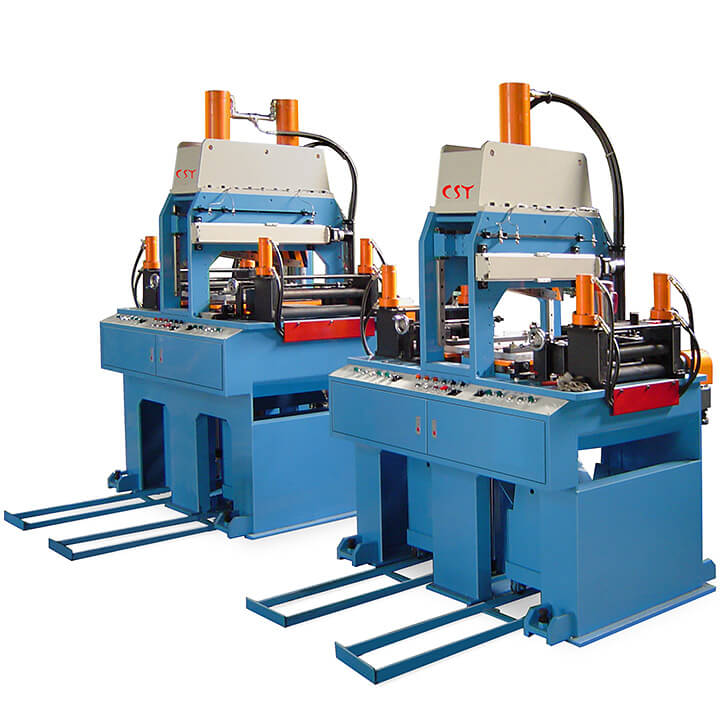

Cutting & Welding Machines

Metal cutting Welder MC-100 ~ MC-250

Metal cutting Welder MC-100 ~ MC-250 Metal cutting Welder MC-300 ~ MC-400

Metal cutting Welder MC-300 ~ MC-400 Metal cutting Welder MC-600 ~ MC-800

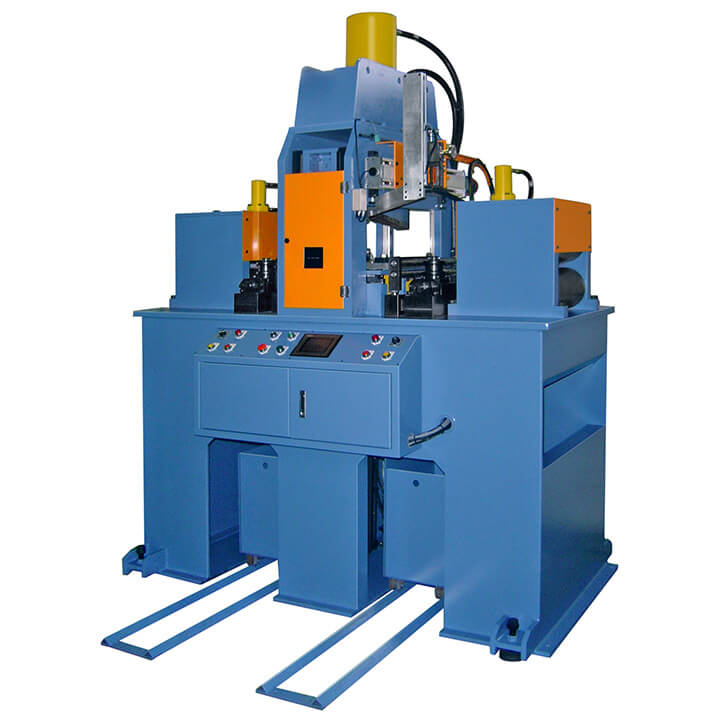

Metal cutting Welder MC-600 ~ MC-800 Metal cutting Welder MC-1000

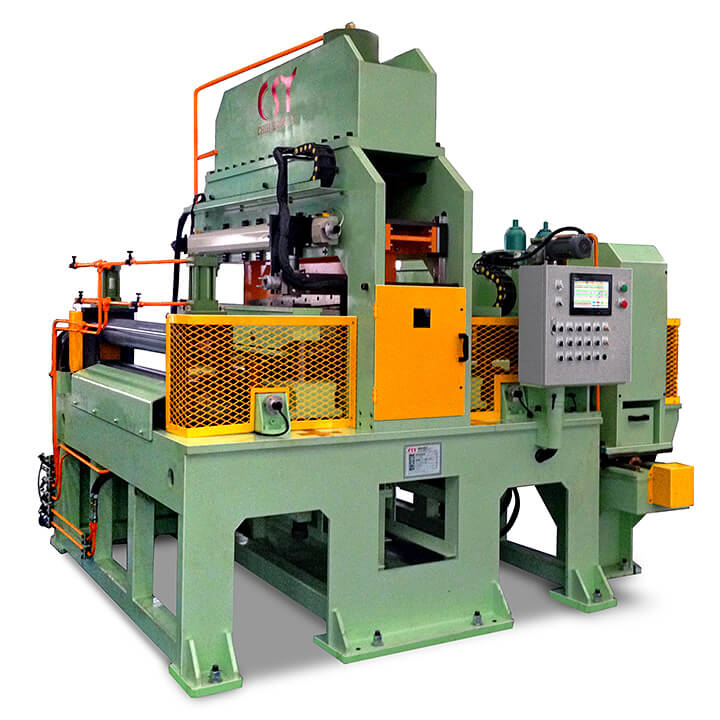

Metal cutting Welder MC-1000 Metal cutting Welder MC-1200

Metal cutting Welder MC-1200 Metal cutting Welder MC-1500

Metal cutting Welder MC-1500Material Cutting/Welding Machine

Cutting/Welding Applications

Utilize Rapid Cutting to Joint and Welding Coil.

METAL STRIP JOINT/WELDING MACHINE

POWER CUTTING

Upper cutting style cutter installed on the mechanism. It is applied for the steel plate feeding direction from left to right or right to left. The cutting blade is driven by hydraulic cylinder.

Cutter mechanism consists of two upper cutting blades and 1 lower cutting blade. Upper cutting blade is designed with dual-blades for a longer cutting life. Three blades design is to avoid cutting distortion. Two hold-clamps with spring to ensure the perpendicular of the work-piece when cutting.

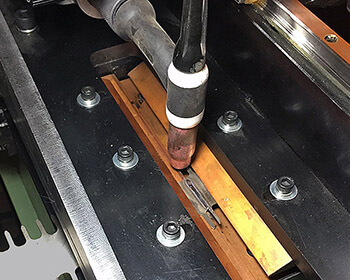

WELD CLAMPING

The position of the hold-clamp at inlet and outlet end is permanently fixed to extend life. There are two 8mm copper alloy back-up blocks. It can rise individually to clamp work-piece.

- AUTOMATIC BACK-UP BAR INSERT

- Back-up blocks are designed to move up and down independently. Since the mechanism is divided into two blocks by the center of weld bead, it can also use the machine work-piece center to position. No other special locating device is needed for this mechanism.

- PEDAL

- This allows the operator to use his both hands to operate the location of the steel plate. The other design, the operator has to touch the switch by hand, this might cause dislocation when welding due to operated by single hand.

- DOUBLE CLAMPING FORCE

- The dual-pneumatic cylinders or hydraulic cylinders we used in the machine can provide double clamping force. It can ensure the location of the work-piece won’t be moved.

GUN SHIFTING APPAR ATUS AND GUN COMBINATION

Welding gun shifting apparatus is in using the method that the plasma is shifted by the belt driven by DC motor. This will reduce efficiently the burn back at the edges of the work-piece.

The welding gun apparatus is moved by linear slide way, thus the position of the welding gun can be set up by manually moved the welding gun. It will automatically touch and induct the electric arc to close when the position of the limit switch is adjusted. No need to change the weld stop position when alter the width of the work-piece. No need to raise the welding gun after welding due to the welding hold-clamp is fixed.

WELDING POWER MACHINE

Inverter type DC argon welding machine. It contains current adjusting button, high-frequency arc start apparatus, and electric gas control valve. The shift Delay timer is controlled that the welding gun starts shifting only after the electric arc is started.

OTHER SUPERB HANDY DESIGNS

Apart from the air cleaning hose, there are other handy designs as below:

TUNGSTEN BAR ALTIMETER : To choose the suitable interval set up.

WORKING LAMP : To reduce eyestrain.

PROTECT GOGGLES : To avoid damage from arc.