Plasma Welding Machines

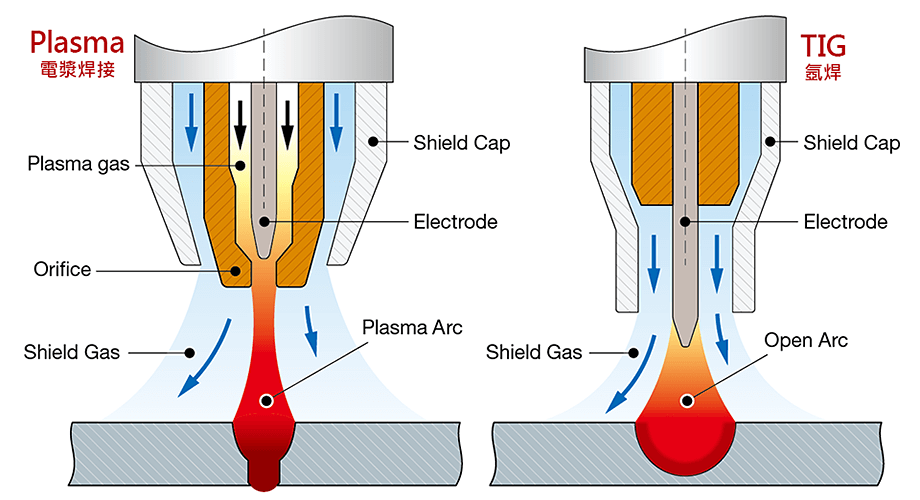

Plasma ARC is more stable and is not as easily deflected to the closest point of base metal. Greater variation in joint alignment is possible with plasma arc welding. This is important when making root pass welds on pipe and other one-side weld joints. Plasma welding has deeper penetration capabilities and produces a narrower weld. This means that the depth-to-width ratio is more advantageous.

Advantages of plasma arc welding when compared to gas tungsten arc welding stem from the fact that PAW has a higher energy concentration. Its higher temperature, constricted cross-sectional area, and the velocity of the plasma jet create a higher heat content. The other advantage is based on the stiff columnar type of arc or form of the plasma, which doesn’t flare like the gas tungsten arc.

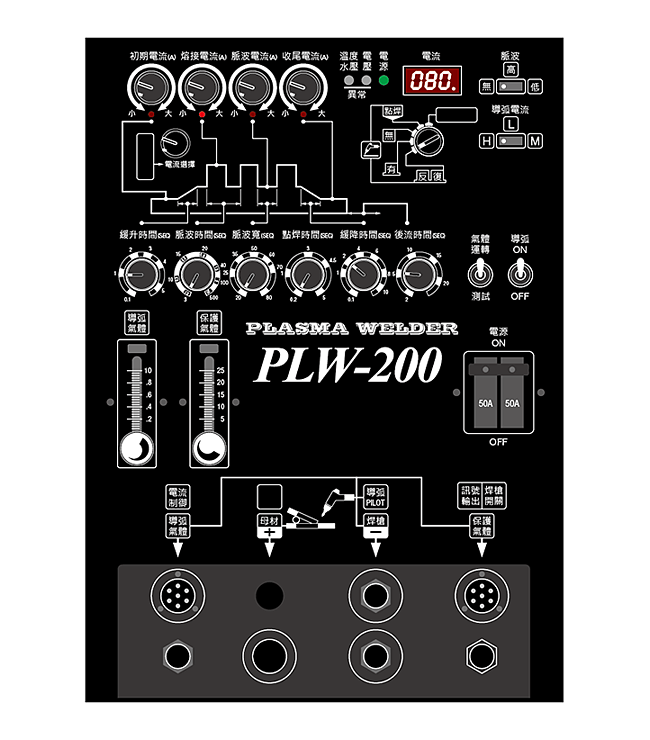

INVERTER AC/DC Plasma Welding Machines

- PLW-200 Plasma Welding Machine

- Crater Control : Spot/Off/On/Repeat.

- Up-Slope, Down-Slope Time Current

- 380V/440V auto-warning protection.

- Over current protection

- Torch Cooled : Water cooling.

- Remote current control device.

- Connections to automatic weld machines.

- Customizable Power 380V/440V。

- PLW-500 Plasma Welding Machine

- Crater Control : Spot/Off/On/Repeat.

- Up-Slope, Down-Slope Time Current

- 380V/440V auto-warning protection.

- Over current protection

- Torch Cooled : Water cooling.

- Remote current control device.

- Connections to automatic weld machines.

| Model | PLW-200 | PLW-500 | ||

|---|---|---|---|---|

| Input Voltage | 220V±10% 50/60Hz | 220V±10% 50/60Hz | ||

| Input Phase | 1 Ø | 3 Ø | 1 Ø | 3 Ø |

| Input Power(kVA) | 10 | 17 | 12.5/8.5KW | 37/25KW |

| Duty Cycle | 100% | 60% | 100% | 60% |

| Initial Current | 5-220A | 5-220A | 5~500A | |

| Welding Current | 5-220A | 5-220A | 5~500A | |

| Pluse Current | 5-220A | 5-220A | 5~500A | |

| Crater Current | 5-220A | 5-220A | 5-500A | |

| Without Load Voltage | - | 110V | ||

| Max Load Voltage | - | 40V | ||

| Up-Slope Time | 0.1~5sec | 0.1~5sec | ||

| Down-Slope Time | 0.2~10sec | 0.2~10sec | ||

| TIG Spot Time | 0.2~5sec | 0.2~5sec | ||

| Pre-flow Time | 0.1~2sec | 0.1~2sec | ||

| Post-flow Time | 2~20sec | 2~20sec | ||

| Pulse Frequency | 0.5~500Hz | 0.5~500Hz | ||

| Pulse Rate | 20-80% | 20-80% | ||

| Crater Control | Spot/Off/On/Repeat | Spot/Off/On/Repeat | ||

| Current Remote Control | Available | Available | ||

| Torch Cooled | Water Cooling | Water Cooling | ||

| Dimensions (L × W × H) | 530×370×620(mm) | 630×400×750(mm) | ||

| Weight | 46Kg | 81Kg | ||

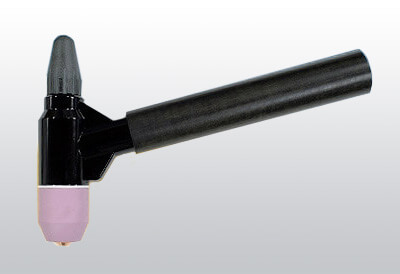

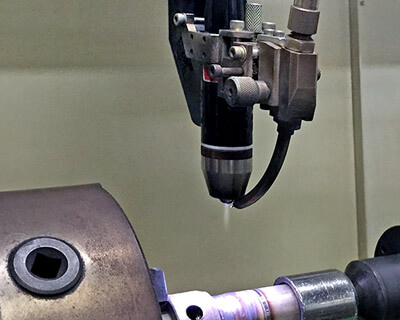

Plasma Welding Torches

50WH

50WH 50KWH

50KWH 100WH

100WH 503WH

503WH 51WH

51WH 51KWH

51KWH 101WH

101WH 504WH

504WHTorches can be selected depending on welding conditions

| Type | Max. current usable (A) | Rated duty cycle (%) | Torch head weight (g) | Torch Shape | Remarks | |

|---|---|---|---|---|---|---|

| Horizontal type | Vertical type | |||||

| 50WH | 100/80 | 60 | 360 | ● | Applicable to keyhole welding and heat conducting welding. | |

| 51WH | 100/80 | 60 | 370 | ● | ||

| 50KWH | 100/80 | 60 | 400 | ● | Applicable to keyhole welding, heat conducting welding, fillet welding and welding in a confined area. | |

| 51KWH | 100/80 | 60 | 410 | ● | ||

| 100WH | 180 | 60 | 500 | ● | By using a narrow-end insert tip, it is possible to apply to fillet welding and welding in a confined area. (In this case,max.current usable is 120A) | |

| 101WH | 180 | 60 | 520 | ● | ||

| 107WH | 170 | 60 | 650 | ● | Indirect water-cooled type. | |

| 503WH | 500 | 50 | 800 | ● | ||

| 504WH | 500 | 50 | 810 | ● | ||

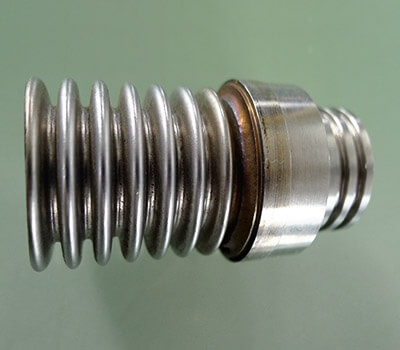

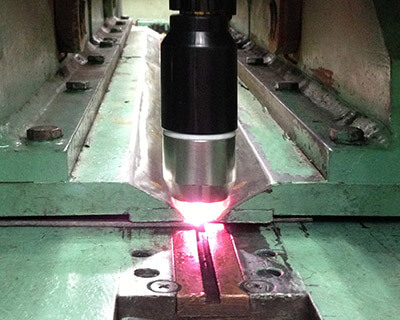

Welding Samples

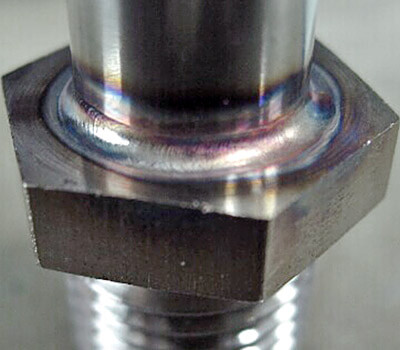

8mm Welding Front

8mm Welding Front 8mm Welding Back

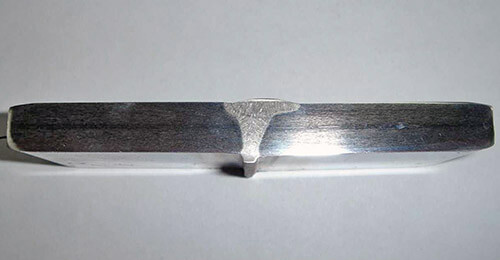

8mm Welding Back 8mm Welding Cross Section

8mm Welding Cross Section 9mm Welding Front

9mm Welding Front 9mm Welding Cross Section

9mm Welding Cross Section