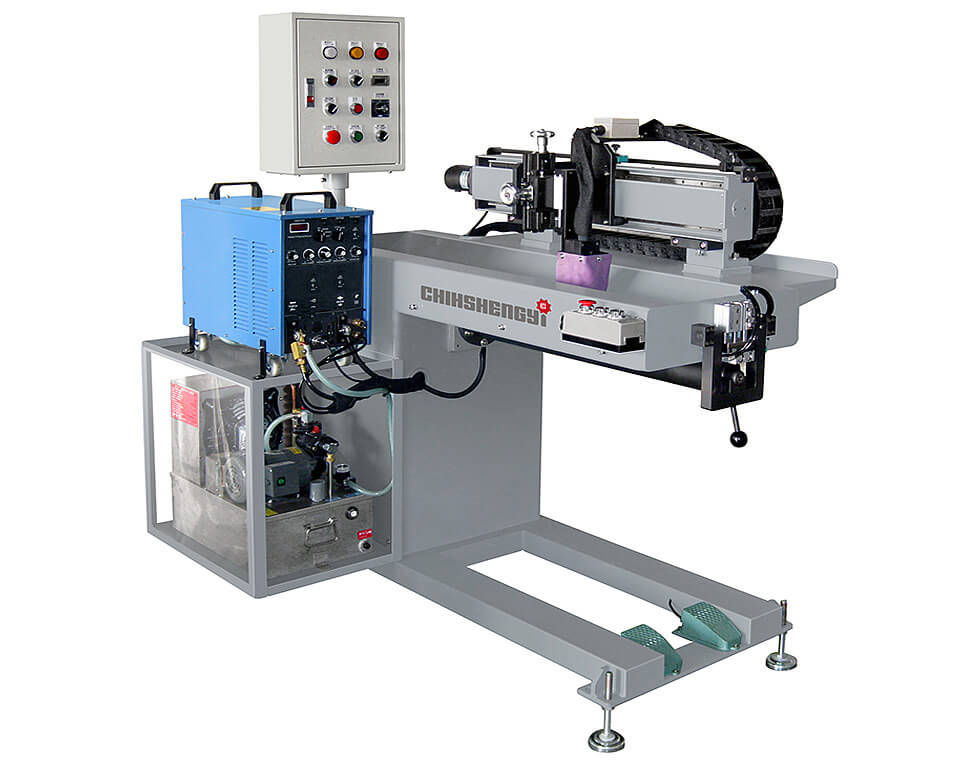

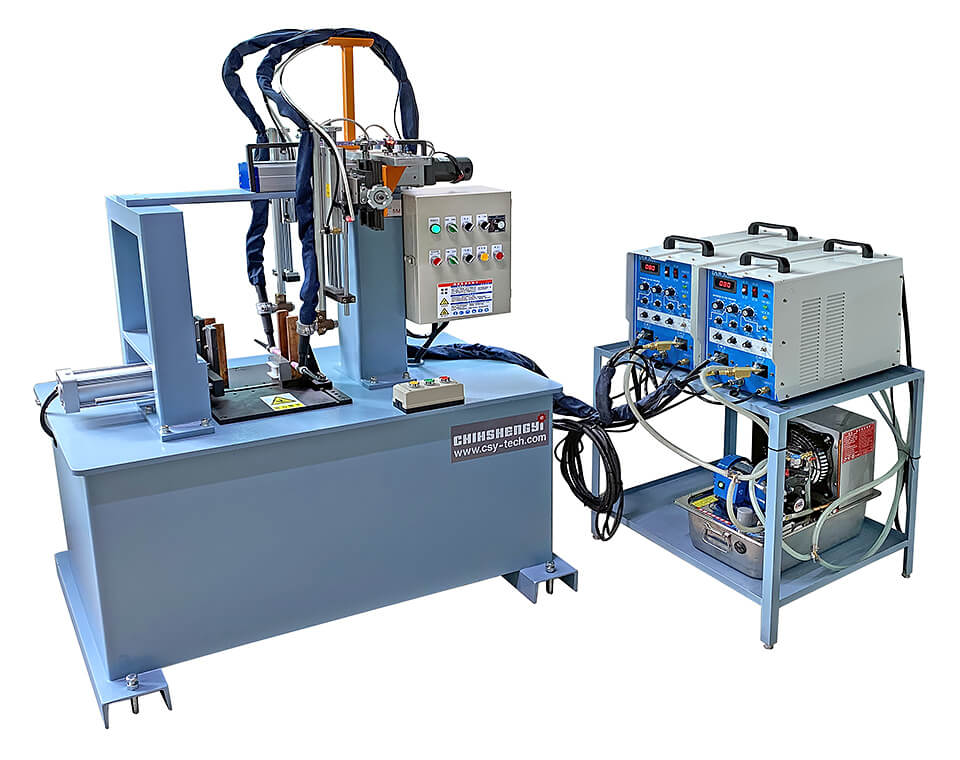

Auto Longitudinal Seam Welder

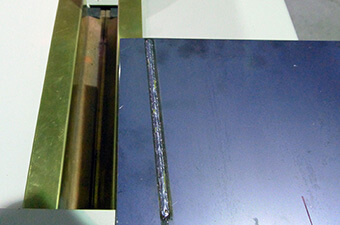

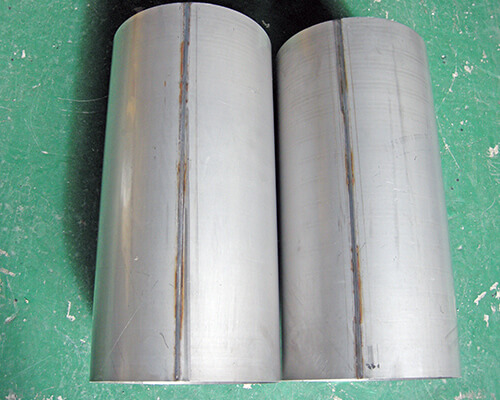

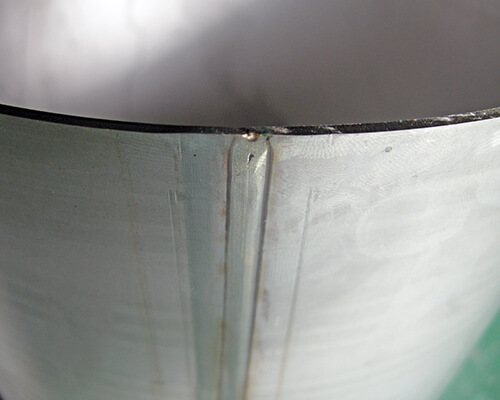

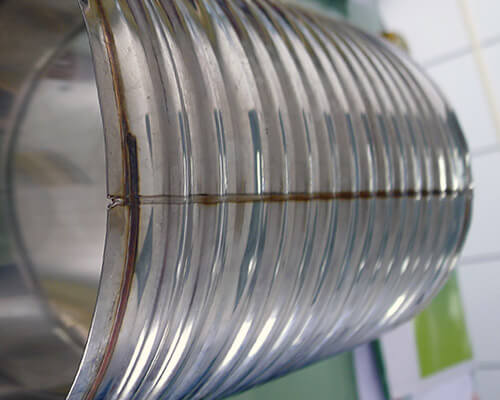

This machine is specially designed to weld the straight seam of the cylinder, hot-water heater, drum, and square container. Back-up rod adopts water cooling method. Keyboard style pressure hold-down. Back-up rod can be changed as per requirement. Welded seam is flat and straight. Good weld penetration and weld quality.

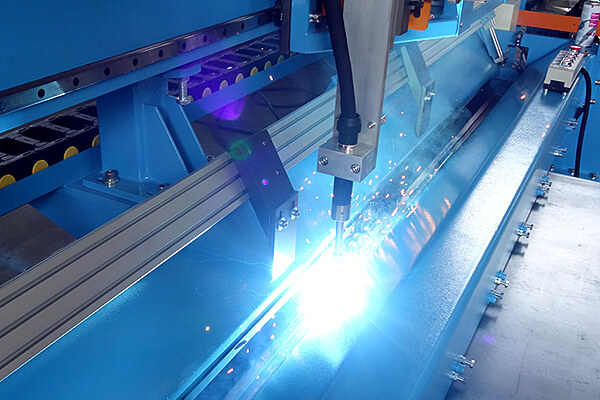

Auto filler optional : Can work with plasma/TIG/CO2/submersible-arc welder.

Motor-driven ball screw drives welding gun to move forward along linear slide-way, presenting a neat welding run. Arc-signal monitoring, incrementally adjustable, and fast returning to preset position.

Applications: Stainless-steel submersible motors, solar-power generators, electric water-heater storages, auto shock absorbers, inner cylinders for drinking-water dispensers, auto/motorcycle fuel tanks, wheels, exhausts, air-conditioning duct, thermo-bottles, filter screens, kitchen counters, stainless-steel trash bins, bleaching & dyeing vats, motor casings, and gas cylinders.

Capabilities/Equipment Instructions

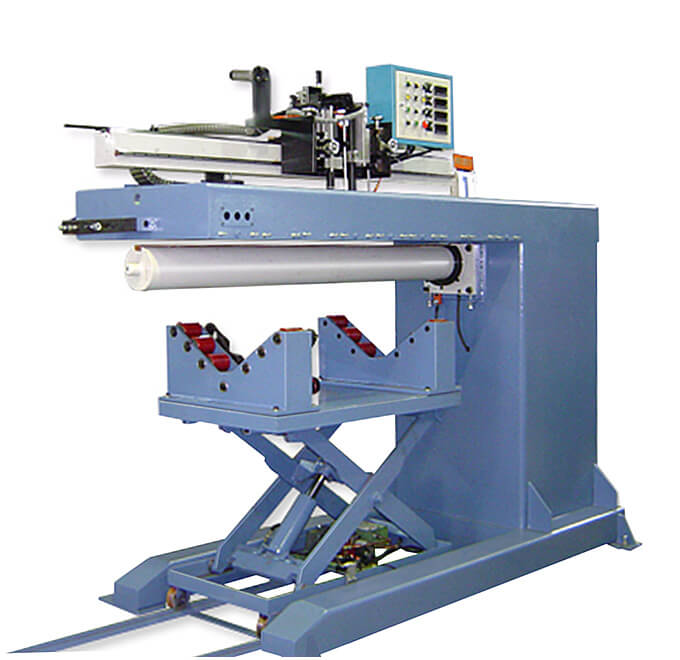

- Traveling track way : Driving member consists of linear slide way and ball bearing worm. Smooth travel no jerk. High efficient transmission.

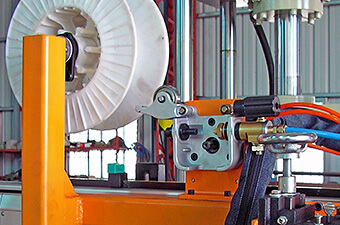

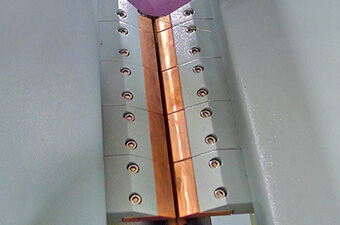

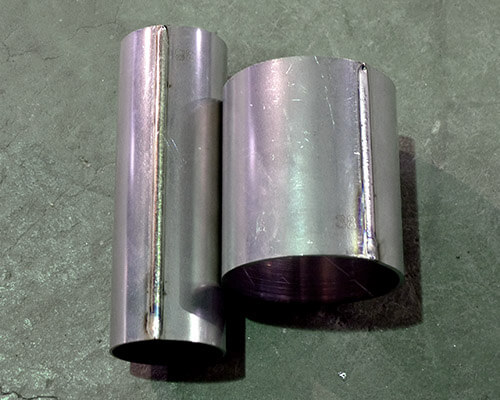

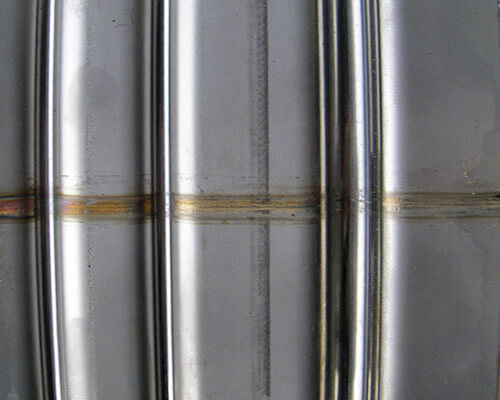

- Circular Back-up Rod : In using of water cooling method for water circulation system. Good cooling effect results in good weld joint quality.

- Back-up copper : The design is subject to change based on the contour, sheet metal thickness, welding method of the work piece.

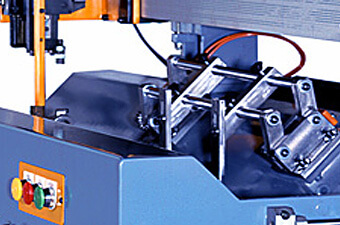

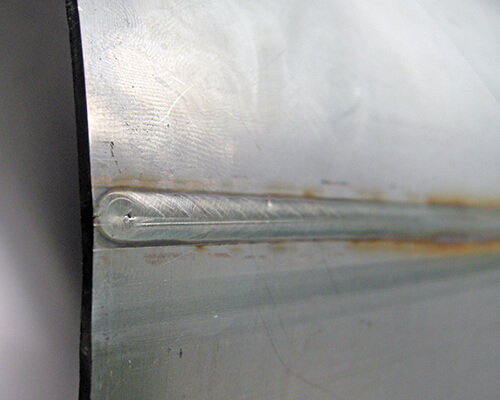

- Pressure Hold-down : The keyboard style pressure hold-down in using of the air bag results in uniform pressure distribution. The weld joint is flat and even.

- Center Pin : To use center pin cylinder operation to center location the work piece. Easy operation and precise orientation.

- Work-piece pre-spots welding: To pre-weld the front guide arc board and the tail board. A straight line can be placed on the front guide arc board and the tail board in order to align the center line.

- Work piece location board: location board to fix the length of the work piece is done by manual. Location is adjustable as per the length of the work piece.

- Tail fastener : In using of pneumatic fastener.

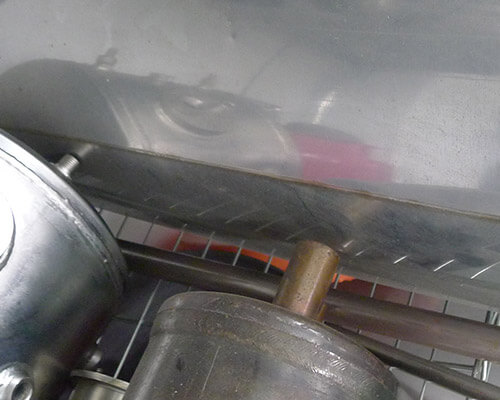

- Up/down location of the welding gun: By up/down travel of the cylinder. Travel: 50mm.

- The position/angle adjustment of the welding gun: The position of the welding gun is adjustable to X/Y direction. Adjustable weld angle. S=50x50mm

- Operator : Stand up when working to maintain efficiency.

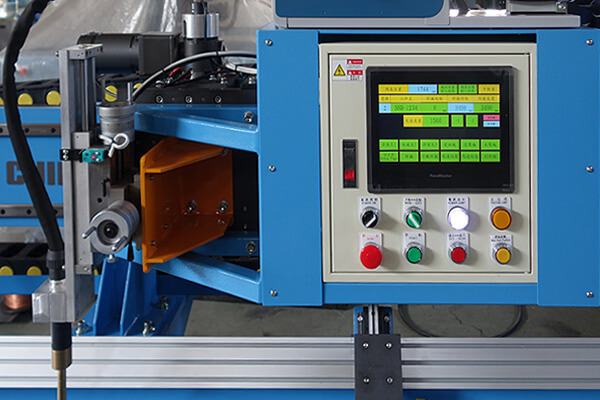

- Easy operation. Just adjust the weld length, weld condition,. and weld gun position to produce stable and good quality product.

- Control method : Electric control: In using of PLC electric control system. It is a easy system for operating and upkeep.

Specifications

| Model | Working Length | Working Diameter | Workpiece Thickness | Input Air supply | Input Power V | Transmission Power W |

|---|---|---|---|---|---|---|

| SL-300 | 300 | 40~800 | 0.3~0.6 | 5kg/cm² | 110~440V 50/60Hz | 65 |

| SL-600 | 600 | 60~800 | 0.4~0.6 | 5kg/cm² | 110~440V 50/60Hz | 65 |

| SL-1000 | 1000 | 80~800 | 0.6~0.8 | 5kg/cm² | 110~440V 50/60Hz | 65 |

| SL-1300 | 1300 | 100~1000 | 0.8~1.0 | 5kg/cm² | 220~440V 50/60Hz | 65 |

| SL-1600 | 1600 | 150~1000 | 1.0~1.2 | 5kg/cm² | 220~440V 50/60Hz | 65 |

| SL-2000 | 2000 | 200~1500 | 2.0~3.0 | 5kg/cm² | 220~440V 50/60Hz | 90 |

| SL-3000 | 3000 | 300~2000 | 3.0~4.0 | 5kg/cm² | 220~440V 50/60Hz | 180 |

| SL-4000 | 4000 | 500~3000 | 4.0~6.0 | 5kg/cm² | 220~440V 50/60Hz | 180 |

Acceptable special customized equipment.

TIG Double Gun Linear Automatic Welding Machine, transformer, silicon steel sheet, motor

TIG Double Gun Linear Automatic Welding Machine, transformer, silicon steel sheet, motor Hydraulic Cylinders Lock

Hydraulic Cylinders Lock Welding Rolling Machine

Welding Rolling Machine

Precision PLASMA LASER Welding Machine

Precision PLASMA LASER Welding Machine Linear Automatic Welding Machine

Linear Automatic Welding Machine TIG Double Gun Linear Automatic Welding Machine

TIG Double Gun Linear Automatic Welding Machine Vertical Type Linear Welding (Large Diameter Air Duct)

Vertical Type Linear Welding (Large Diameter Air Duct)

Welding Applications

Titanium alloy wheels, Titanium rim, α Titanium, β Titanium , Titanium alloy, Golf bag cart, Golf ball carrier, Golf equipment...

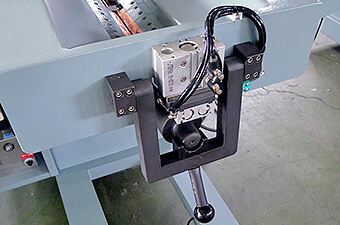

Machine Sensing Component

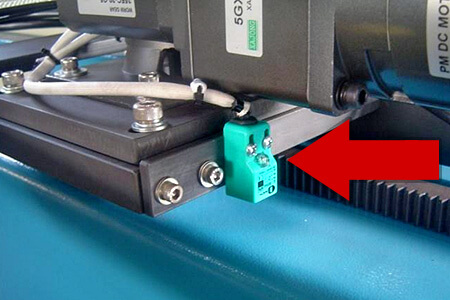

- SENSOR

- Torch forward/revers limit point sensing device, before and after each one.

- SENSOR Model:QL-1805NA

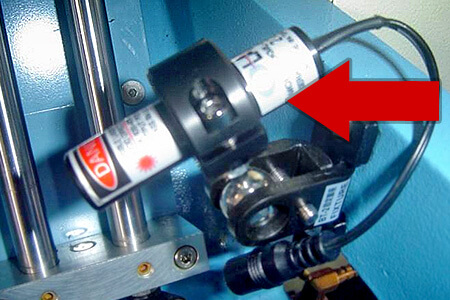

- Laser Marking Device

- Used laser line hit a straight line for work-piece positioning and correction etc...

- Laser Marking Device Model : KML-2505

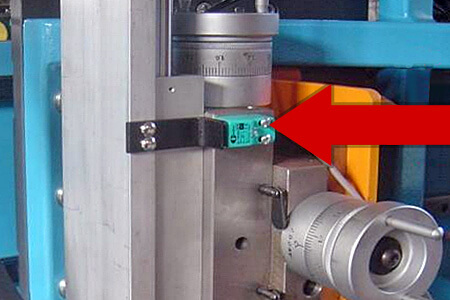

- Rotary Encoder

- Calculated torch displacement distance.

- Rotary Encoder Model : TRD-S1000B

- SENSOR

- Make sure torch actuation indeed.

- SENSOR Model : OL-1805NA

- SENSOR

- Make sure position plate actuation indeed.

- SENSOR Model : D-J79

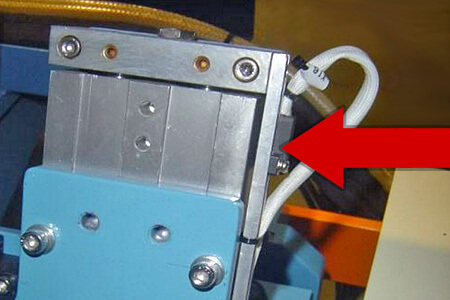

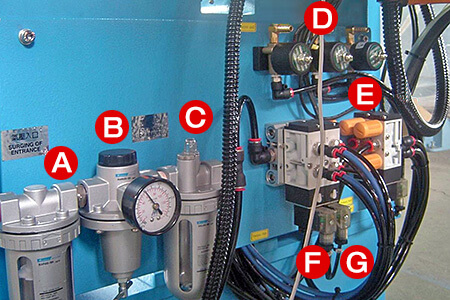

- Enter Pressure Electromagnetic Valve

- A Pressure Filter Impurities

- B Regulator pressure adjustment

- C Lubricator gas lubricated

- D Solenoid Valve Gas

- E Solenoid Valve Left/Right Pressure Plate

- F Solenoid Valve Position Plate

- G Solenoid Valve Torch UP/DOWN