Industrial Robot Arm Models

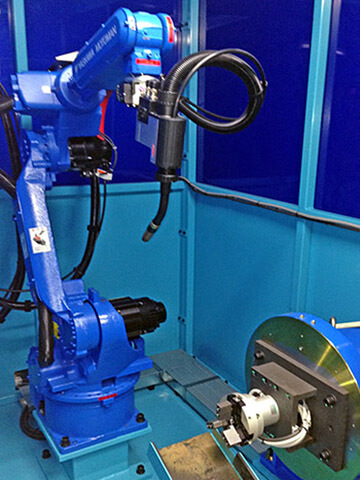

MOTOMAN Arc Welding Robot Models

Motoman Robotic Welding, with automated welding industry firsts such as patented multiple robot control and MA-series robots. The flexibility of the VA1400 model can be used to reduce floorspace and achieve higher robot density for increased production. Unique ELBOW axis of the arm also allows the robot to reach around tall parts or reach into boxy parts.

- MOTOMAN-MA2010

- Controlled Axis : 6

- Payload 10kg

- Horizontal Reach : 2000mm

- Controller : DX200

- MOTOMAN-MA1440

- Controlled Axis : 6

- Payload 6kg

- Horizontal Reach : 1440mm

- Controller : DX200

- MOTOMAN-MA1800

- Controlled Axis : 6

- Payload 15kg

- Horizontal Reach : 1807mm

- Controller : DX100

- MOTOMAN-MA1900

- Controlled Axis : 6

- Payload 3kg

- Horizontal Reach : 1904mm

- Controller : DX100

MOTOMAN Solutions In Motion

Yaskawa Motoman offers a wide range of industrial robotic arm models for high-speed precision assembly and small part handling including high-performance robots.

- MOTOMAN-MH6

- Controlled Axis : 6

- Payload 6kg

- Horizontal Reach : 1422mm

- Controller : DX100

- MOTOMAN-MH50

- Controlled Axis : 6

- Payload 50kg

- Horizontal Reach : 2061mm

- Controller : DX100

- MOTOMAN-MH165

- Controlled Axis : 6

- Payload 165kg

- Horizontal Reach : 2651mm

- Controller : DX100

- MOTOMAN-HP20D

- Controlled Axis : 6

- Payload 20kg

- Horizontal Reach : 1717mm

- Controller : DX100

- MOTOMAN-UP350D~500

- Controlled Axis : 6

- Payload 500kg

- Horizontal Reach : 2542mm

- Controller : DX100

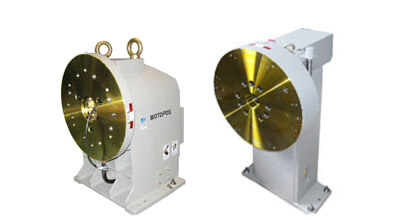

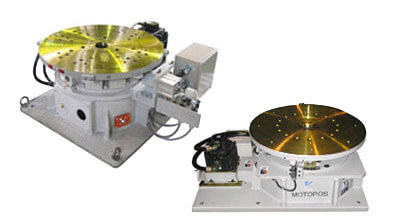

MOTOPOS Turntable/Positioner

Robot and MOTOPOS weld in coordination at a constant speed, allowing the workpiece and the torch to keep the best posture at all times. This reduces partial penetration and distortion, and greatly improves welding quality. Control system designed specially for MOTOMAN robots and MOTOPOS.

Single Axis Vertical Type

Single Axis Vertical Type Single Axis Horizontal Type

Single Axis Horizontal Type 2/3 Axis Cantilever Type

2/3 Axis Cantilever Type 2 Axis Standard Type

2 Axis Standard Type

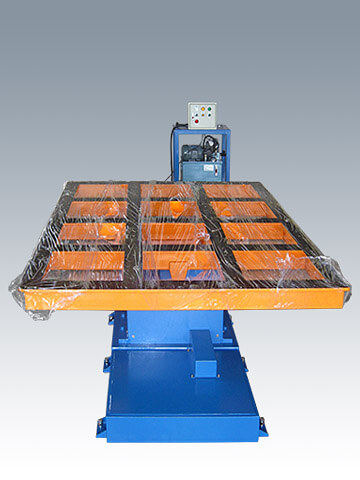

Robot Rotary Table 180 degree flip- Flip angle : 180 degree

- Workpiece size : 200mm(H) × 1000mm(W) × 2000mm(L) ; Including mold

- Table Payload : 300kg (Including mold Workpiece height 200mm)

- Positioning Accuracy : 0.1mm (Workpiece height 200mm)

- Positioning Speed : 180° ≈ 5/Second

- Power Motor : 2HP AC Motor (Reducer with brake)

- Positioning mode : Pneumatic Bolt

- Controller : PLC Link mechanical manual.